Job Hazard Analysis (JHA) breaks a job or task into specific steps, analyzes each step for specific hazards, develops safe work procedures to eliminate or reduce those hazards, and integrates safe work procedures into safety and health programs. JHAs must be developed for each job or task. Supervisors and workers must complete the JHA together.

Basic Steps - Job Hazard Analysis is broken down into 6 major steps:

a. Select the job task to be analyzed.

Prioritize which job tasks to analyze. ose job tasks where accidents and injuries are occurring should be analyzed first. Look at job tasks where there is a potential for serious injury. Look at new job tasks, these are important if a new process requires the development of new procedures and job tasks.

b. Identify the major sequence of steps for each step (Specific job step Description).

Once a job task has been chosen, it must be broken down into logical steps. Limit the number of steps in a JHA to a manageable number. Most jobs can be described in ten or less steps. The job steps must be kept in their proper sequence to ensure a proper analysis. The opportunity to make recommendations will come later in the analysis.

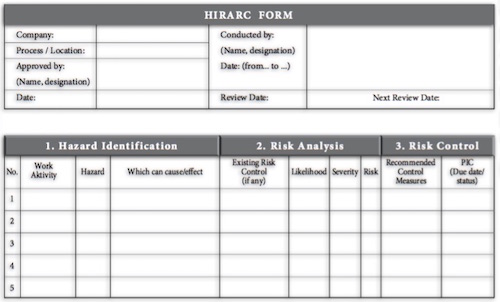

c. Identify the potential hazards for each step (Hazard Identification)

Once the job steps have been chosen, the potential hazards for each step can be identified. Whatever can go wrong may go wrong! What are the potential hazards as a result of each task step? Is the worker exposed to hazardous chemicals? Is the worker subject to poor workstation design? There may only be one, or there may be a large number for each job step.

d. Determine preventative measures to protect against the hazards (Required Precautions)

- The most important aspect of the job hazard analysis is to determine preventive measures to control or eliminate the identified hazards. What actions must be taken to control or eliminate the hazard?

- Eliminate the hazard - Substitute with less hazardous substance/material.

- Contain/Enclose the Hazard - Use a fume hood or proper shielding.

- Revise Safe Work Procedures - Adding additional steps.

- Reduce Worker Exposure - This is the least effective option in most cases, but may have to be used when permanent work process change is impossible or impracticable. Examples of this option include job rotation, where worker exposure is reduced, and the provision of personal protective equipment (PPE) to workers.

e. Develop a worker-training program

Reformat the job hazard analysis into a training program to help the employee eliminate or reduce hazards.

f. Re-evaluation

Re-evaluate the job descriptions and modify the job hazard analysis’ accordingly.