- Redesign - Jobs and processes can be reworked to make them safer. For example, containers can be made easier to hold and lift.

- Isolation - If a hazard cannot be eliminated or replaced, it can some times be isolated, contained or otherwise kept away from workers. For example, an insulated and air-conditioned control room can protect operators from a toxic chemical.

- Automation - Dangerous processes can be automated or mechanized. For example, computer-controlled robots can handle spot welding operations in car plants. Care must be taken to protect workers from robotic hazards.

- Barriers - A hazard can be blocked before it reaches workers. For example, special curtains can prevent eye injuries from welding arc radiation. Proper equipment guarding will protect workers from contacting moving parts.

- Absorption - Baffles can block or absorb noise. Lockout systems can isolate energy sources during repair and maintenance. Usually, the further a control keeps a hazard away from workers, the more effective it is.

- Dilution - Some hazards can be diluted or dissipated. For example, ventilation systems can dilute toxic gasses before they reach operators.

Types of Control : Engineering Control

abah

7:33 AM

Tags

Reactions

You may like these posts

ARCHIVE

Copyright © 2016 safetyrisks All Right Reserved

Popular Posts

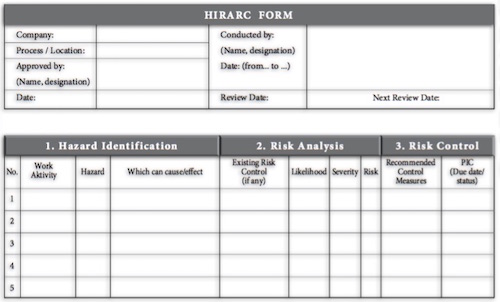

HIRARC : Documenting Process

11:45 AM

Process of HIRARC

2:28 PM

Documenting HIRARC

5:50 AM

Mechanical Hazards

4:20 AM

Categories

- PPE

- noise

- workplace safety

- electrical safety

- construction safety

- Occupational Safety and Health

- road safety

- OSHA

- chemical safety

- fire safety

- lab safety

- office safety

- safety engineering

- biological safety

- child safety

- computer safety

- environment

- escalator safety

- food safety

- forklift safety

- highway safety

- home safety

- hygiene

- industrial safety

- kitchen safety

- mechanical safety

- patient safety

- scaffolding safety

Tags

- HIRARC

- safety topics

- construction

- noise

- hazards

- Industrial Hygiene

- LOTO

- job hazard analysis

- demolition

- electrical

- fire

- hot work

- confined space

- first aid

- fishing

- flammable

- hearing impairment

- radiation

- safety officer

- safety signage

- Eye Protection

- Hand and Power Tools

- OSHA Certification

- administrative controls

- assessment

- biological

- body protective equipment

- breathing apparatus

- building evacuation

- chemical exposure

- compressed gases

- crane

- drowning

- emergency

- escalator

- evacuation

- excavation

- explosive

- forklift

- ghs hazard symbols

- how to

- physical hazards

- rescue

- risk management

Created By eaadhar | Distributed By Blogger Themes